Flow Rate: 63~210 L/min

Pressure Range: 1,000~2,800 Bar

QUALITY ACCURANCE

TIMELY DELIVERY

Technical Data

| MODEL | POWER | FOLW RATE @ WORKING PRESSURE | |

| F400-HDS-23 | 360KW | 63 L /min @ 2,800 Bar | 16.6 GPM @ 40,000 Psi |

| F400-HDS-27 | 429KW | 85 L/min @ 2,500 Bar | 22.5 GPM @ 36,000 Psi |

| F400-HDS-35 | 360KW | 135 L /min @ 1,400 Bar | 35.7 GPM @ 20,000 Psi |

| F400-HDS-37 | 429KW | 157 L/min @ 1,400 Bar | 41.5 GPM @ 20,000 Psi |

| F400-HDS-39 | 360KW | 180 L /min @ 1,000 Bar | 47.6 GPM @ 15,000 Psi |

| F400-HDS-43 | 429KW | 210 L/min @ 1,000 Bar | 55.5 GPM @ 15,000 Psi |

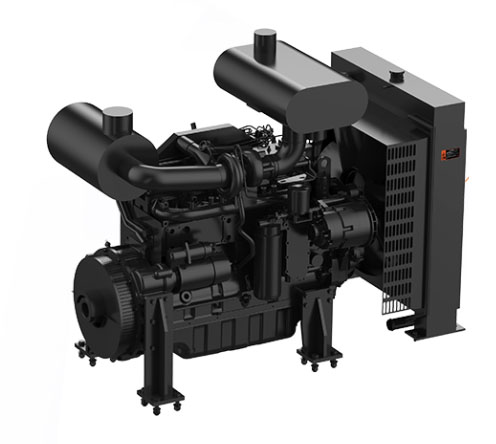

F400-HDS ----ULTRA-HIGH PRESSURE (UHP) WATERJET PUMP UNIT

THREE PLUNGER PUMP FLUID END

The imported fluid end is used for ultra-high pressure import Uni-valve and other key parts are used for medium and high pressure,with high performance and long service life Cemented carbide or zirconia.Ceramic plunger,smooth finish can reach 0.01μm,effectively improving the3 life of wearing parts.

Single seal design of trapezoidal structure,accurate positioning without channelizing,and long service life Equipped with precise pneumatic pressure regulating valve,it is safe and reliable with precise pressure regulating and overflow functions.

The conversion between different fluid ends be realized within half an hour.

POWER END

Precise gear ring design,superior performance,low noise 42CrMo,4:1 froged crankshaft.

Precise gear ring design,superior performance,low noise 42CrMo,4:1 froged crankshaft.

Integrated crankcase design,effectively prevent plunger biased wear

The thrust of the crankcase is up to 150 KN

Equipped with force lubrication system,oil temperature,oil pressure,pressure differential monitoring system.

HIGH PRECISION PRESSURIZED THREE STAGE INTEGRATED DOUBLE FILTER ELEMENT FILTER

Intergrated filter cartridge design,simple structure,easy maintenance.

Design of graded filter element,high filtration efficiency and long service life.

Simplify water supply pipeline to avoid cavitation effect and accumulation of impurities.

Equipped with imported WIKA pressure gauges and pressure monitoring.

Equipped with the water tank to form a three-stage filtration system.

Mass flow and high quality booster pump,can reach 2~3 times the water demand.

FILTER WATER TANK

Double filter bag filtration system is built into the water tank to improve water supply quality.

Equipped with imported mechanical float ball valve to effectively eliminate the “water hammer effect”.

Equipped with liquid level and water temperature monitoring ,real-time monitoring of water supply status.

Stainless steel spray layered water tank,stable structure,long service life.

ORIGINAL IMPORT INTEGRATED SPECIAL CONTROL SYSTEM

Professional and special customized monitoring instrument,highly integrated control and monitoring.

Real-time monitoring of diesel engine and high-pressure pump operation,far away from high pressure terminal,safer operation .

Comprehensive monitoring and alarm protection system;

Liquid level switch:Monitor the state of water level to ensure that the unit will not run idle.

Water temperature switch : Monitor the water temperature to ensure that the unit will not run over temperature.

Water pressure switch:monitor the water inlet pressure and ensure the water supply pressure.

Water pressure differential switch :monitor intergral filter,alarm prompt to change filter element.

Oil pressure switch:Monitor the forced oil pressure status.

Oil temperature switch:Monitor oil temperature of crankcase of high pressure pump

Differential oil pressure switch:Monitor the status of oil filter.

DIESEL ENGINE

Cummins diesel construction machinery is adopted to meet the national III emission standards,rated power 335,peak torque 2300 N.m.@1500rpm .

High pressure common rail fuel system (HOCR) is adopted to ensure the accelerator responds fast at different RPMs,btrrer power performance and fuel economy,and lower noise.

The mature intelligent electronic control technology can switch the working mode according to the environment and operating conditions,and has the functions ofg self diagnosis,alarm andremote monitoring.

Cummins equipped with 3000 rpm,0.9m3/min air compressor to meet the requirements of surface and tube bundle cleaning peuematic rotary gun.

HIGH STRENGTH INTEGRAL BASIC PALLET

The Basic Pallet is designed with and integral reinforced steel beam to ensure that the pump and motor are firmly fixed.

The important welding joints of the Basic Pallet shall be double-sided full welding and corrected after welding.

The Basic Pallet adopts vibration aging treatment to remove the internal residual stress to ensure the chassis is not deformed.

The Basic Pallet contains toolbox,miniaturized air pump,which makes the whole equipment simple.

COMTAINER COVER

Removable container cover assembly for easy replacement.

The container is customized to facilitate the operation and maintenance of the equipment.

The container adopes cold-rolled plate as a whole sandblasted plastic spray treatment to meet the requirements of Marine anti-corrosion.