Flow Rate: 27~220 L/min

Pressure Range: 60~500 Bar

QUALITY ACCURANCE

TIMELY DELIVERY

Technical Data

| MODEL | POWER | FOLW RATE @ WORKING PRESSURE | |

| F1502-HES-18 | 30KW | 27 L /min @ 500 Bar | 7.13 GPM @ 7,300 Psi |

| F1502-HES-20 | 30KW | 34 L/min @ 430 Bar | 8.98 GPM @ 6,300 Psi |

| F1502-HES-22 | 37KW | 40 L /min @ 460 Bar | 10.56 GPM @ 6,700 Psi |

| F1502-HES-24 | 45KW | 49 L/min @ 450 Bar | 12.94 GPM @ 6,500 Psi |

| F1502-HES-25 | 55KW | 52 L /min @ 520 Bar | 13.74 GPM @ 7,600 Psi |

| F1502-HES-26 | 55KW | 57 L/min @ 480 Bar | 15.06 GPM @ 7,000 Psi |

| F1502-HES-28 | 55KW | 66 L /min @ 420 Bar | 17.44 GPM @ 6,100 Psi |

| F1502-HES-30 | 75KW | 75 L/min @ 500 Bar | 19.81 GPM @ 7,300 Psi |

| F1502-HES-32 | 90KW | 85 L /min @ 500 Bar | 22.46 GPM @ 7,300 Psi |

| F1502-HES-35 | 90KW | 102 L/min @ 430 Bar | 26.95 GPM @ 6,300 Psi |

| F1502-HES-38 | 90KW | 121 L /min @ 350 Bar | 31.97 GPM @ 5,100 Psi |

| F1502-HES-40 | 90KW | 135 L/min @ 330 Bar | 35.67 GPM @ 4,800 Psi |

| F1502-HES-42 | 90KW | 150 L /min @ 300 Bar | 39.63 GPM @ 4,400 Psi |

| F1502-HES-45 | 90KW | 170 L/min @ 280 Bar | 44.91 GPM @ 4,100 Psi |

| F1502-HES-46 | 90KW | 180 L /min @ 250 Bar | 47.56 GPM @ 3,700 Psi |

| F1502-HES-48 | 90KW | 194 L/min @ 230 Bar | 51.26 GPM @3,400 Psi |

| F1502-HES-50 | 90KW | 210 L /min @ 210 Bar | 55.48 GPM @ 3,100 Psi |

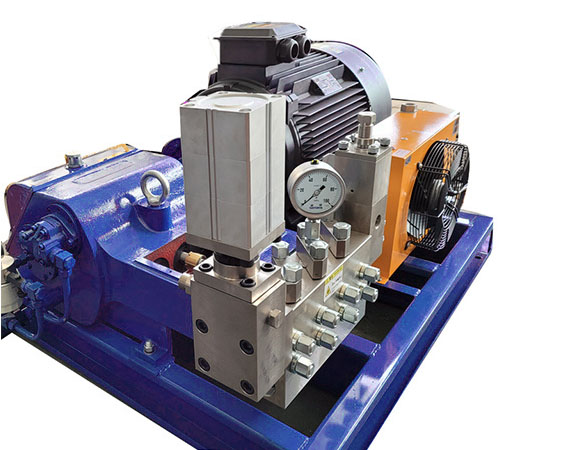

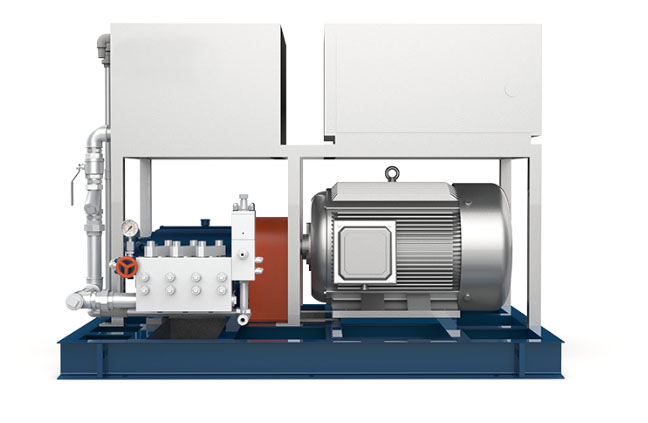

F1502-HES ----HIGH PRESSURE (UHP) WATERJET PUMP UNIT

THREE PLUNGER PUMP FLUID END

The F1502 high-pressure pump’s structure is compact and small. The power end applies either splash lubrication or forced lubrication to make sure the transmission is stable and reliable, meanwhile reducing the friction coefficient and improving the lubrication performance. The lower increasing temperature of the power end is suitable for long-term continuous operation. It can pump clean water, emulsion, and some chemical liquid. It is suitable for high-pressure water jet assisted rock-breaking coal, underground hydraulic cylinder liquid providing, for high-pressure water jet cleaning, metallurgical dephosphorization, powder metallurgy, ship cleaning and derusting, foundation engineering, liquid transportation, engineering excavation. It can combine with various rubber tubes or metal pipes,and apply in oilfield as a wellhead pressure testing pump. Meanwhile it can pump water, emulsions and other chemical liquids.

If the product is in demand, please confirm the proper pressure or flow in the table below and add into inquiry list.

POWER END

The electrical/diesel engine drives the high speed shaft through a pair of herringbone gears to transfer the torque to the crankshaft while reducing the speed. The crankshaft converts the rotating motion into reciprocating motion through the connecting rod mechanism, and the plunger is driven by the crosshead device to complete working cycles.

HIGH EFFICIENCY ENERY-SAVING MOTOR

High efficiency and energy saving motor reasonable structure,beautiful appearance,high efficiency,low noise,high protection level,high insulation level.Rated voltage 380v,rated frequency 50Hz,protection grade:IP55.

INTEGRATED INTELLIGENT ELECTRICAL CONTROL CABINET

Electric cabinet adopts advanced design structure,beautiful and firm structure,reasonable wiring.

The electrical components adopt international famous brand components to ensure the stability of the control system .

The electric cabinet is integratedwith motor monitoring,high-pressure pump monitoring and high-pressure pump regulationg.

Electic cabinet can choose soft start cabinet,frequency conversion start cabinet and other multi-function cabinets.

The electric cabinet can be controlled remotely.

Slect intelligent cloud application .Witto standard electrical cabinet.

LIQUID END

When the plunger moves back under the driving crankshaft, the volume of the inner cavity of the pump gradually increases while the pressure decreases, then a negative pressure is formed, and the drain valve is closed. Due to the pressure difference, the inlet valve opens and the liquid enters into the working chamber. When the plunger continues to move to the return stroke limit position, the suction process is finished and the working chambers full filled with liquid. When the plunger moves forward, the working chamber volume gradually decreases while the pressure increases, the inlet valve closes and the drain valve opens, then the liquid is discharged from the discharge passage. When the plunger reaches the end point, the working chamber has the smallest volume and the largest pressure. The plunger continuously reciprocates, and the suction and discharge processes are alternately repeated, and the high pressure liquid is continuously discharged from the drain passage

COOLING AND LUBRICATION SYSTEM

The gear oil pump runs with the high speed shaft, and the lubricating oil in the power end casing is sucked out to be cooled down through the heat exchanger, and then pass through the filter. The filtered low-temperature lubricating oil enters the crankshaft, bearing bush and other parts that need lubrication. The excess lubricating oil passes through the check valve and returns to the power end casing.

FEATURES

● Flow rate up to 210L/min

● 3 plungers design,Wide variety of complementary ancillaries

QUALITY AND RELIABILITY

Stainless steel pump head, Forced lubrication system,Ceramic material or tungsten carbide plungers, Transmitted stably,Long working life under continuous load.

EQUIPMENT BASIC CONFIGURATION

● Vibration- proof pressure gauge

● Air pump system

● Safety Blasting Diaphragm

● Piping booster pump

● Pneumatic pressure regulating valve

● Protection of water supply system

● Start container

● Water supply piping system

● Stainless steel water tank

● Y shape filter

● Stainless vertical filter

● Skid Mounted or Skid mounted with cover ,Trailer and Cover

Application