PSR-HG 3D NOZZLE

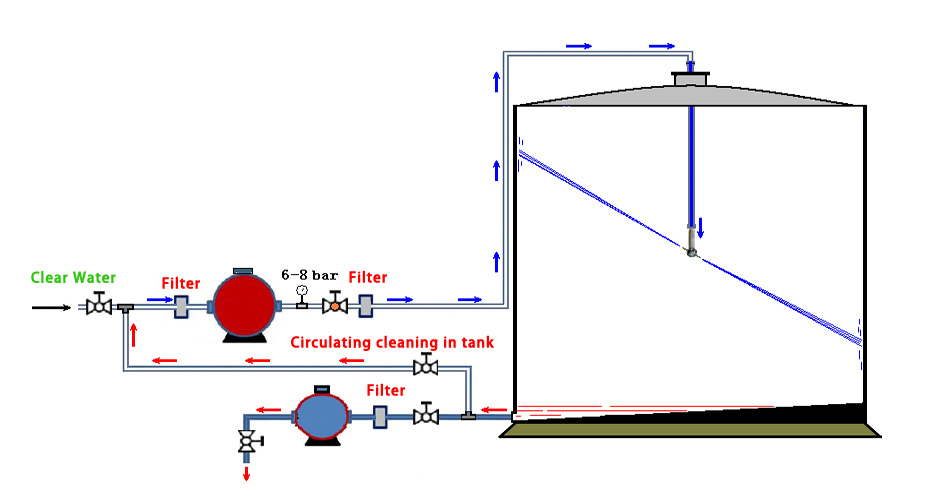

Product principle and application:

PSR-HG type spray head is a fully automatic spray head for three-dimensional water jet cleaning of the inner wall of sanitary grade special tanks, mainly used in tank cleaning fields that require high sanitary conditions such as pharmaceuticals, food, and fermentation. It adopts a unique sealing and internal structure, and all gear boxes are made of oil-free self-lubricating materials, which will not cause secondary pollution to materials due to the leakage of gear grease in the gearbox.

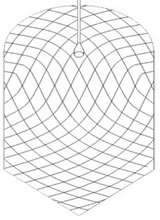

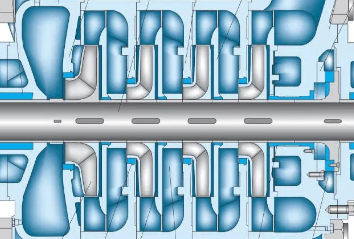

The PSR three-dimensional tank cleaning nozzle utilizes the powerful impact force generated by water jet, and uses the eddy current generated by water flow to drive the rotary drive mechanism to realize revolution and self-transmission to form a double-degree of freedom reticulated spherical track. The three-dimensional space is 360 ° rotary cleaning, and there is no blind spot full coverage. Up to hundreds of cleaning tracks ensure that reliable and effective cleaning is being achieved

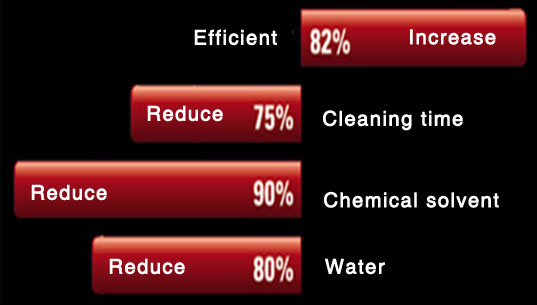

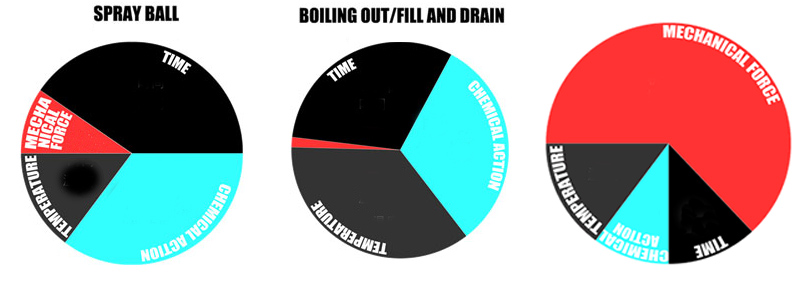

From the SINNER pie chart, it can be seen that by increasing the mechanical scouring effect of cleaning, the cleaning time is reduced, the chemical action and time consumption are reduced, the operation cost is saved, and the efficient cleaning is truly realized.

Application Industry:

Pharmaceutical industry, food industry, fermentation industry, transportation industry, and other cleaning conditions with high hygiene requirements.

Main technical parameters:

Model example:

PSR-HG-05: Basic type

PSR-HG-05-D: rugged and durable,

PSR-HG-05-D-HT: rugged and durable+high-temperature type

PSR-HG-05-D-HT-F: rugged and durable type+high-temperature type+fast type

Main technical parameters:

Material: 316L

Net weight: 4.5 kg

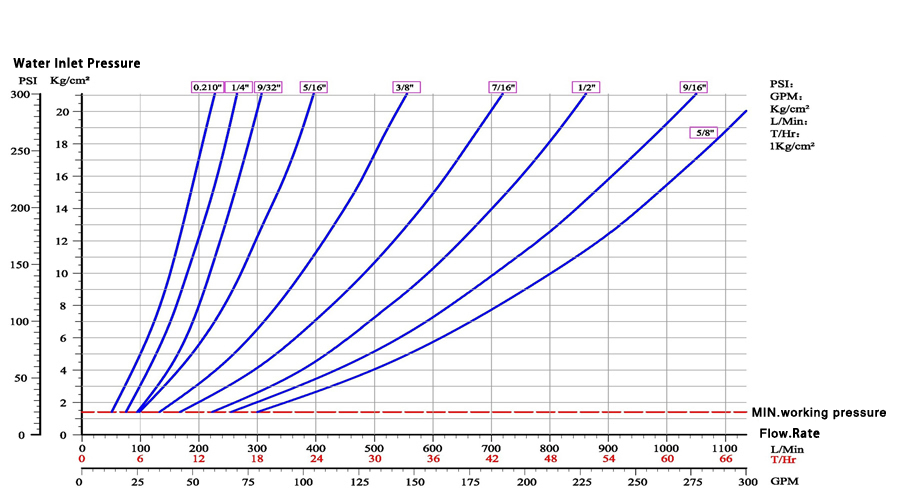

Max.Pressure :<20 Bar

Working Pressure : 5-15 Bar

Working flow: 130-240 L/Min

Working temperature: normal temperature type 0~60 ℃, high temperature type 60~220 ℃

Cleaning track: 252 cleaning tracks per cleaning cycle

Cleaning cycle: 5-12 minutes (forming a complete mesh trajectory is a cleaning cycle)

Interface type: sanitary joint

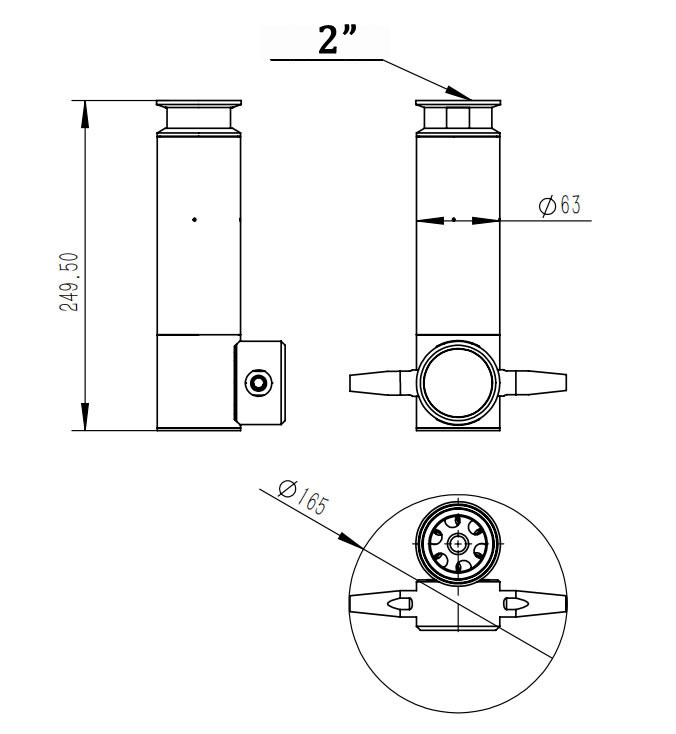

Overall dimension: (mm)

Unique technology and product advantages:

1:The transmission system is made of self-lubricating wear-resistant materials such as ceramics, without the need to add lubricating oil and grease, ensuring no leakage of pollutants and preventing secondary pollution to the cleaning container.

2: The incomparable ratio of revolution and autobiography, up to 252 cleaning tracks, ensures that every part of the tank can be effectively cleaned.

3: The unique multistage centrifugal dynamic pressure balance sealing technology completely insulates the contact between the planetary gear reducer and water, ensuring that there is no harmful material pollution.

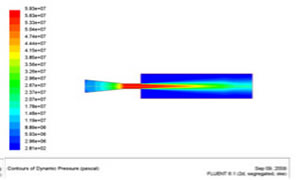

4: The unique fluid rectification molding technology adopts streamlined nozzle and turbulent linear injection to ensure the concentration of water flow for long-distance cleaning and large impact force.

5:The unique eddy current turbine drive technology ensures strong driving force and can realize adjustable speed and torque.

6: Pure stainless steel industrial grade planetary gear transmission, corrosion resistant, rust free, no secondary pollution, strong bearing capacity, long service life, maintenance-free.

7: The internal transmission structure adopts plasma surface spraying technology, which is more wear-resistant and corrosion resistant.

8:Unique compensated mechanical seal technology, acid and alkali resistant, corrosion resistant, high temperature resistant, durable and maintenance-free.

9:The medium hydraulic friction transmission can effectively protect the overload and prevent the reducer gear from being damaged when the nozzle is blocked.

10:The double nozzles of the nozzle are arranged with 180 degrees of balanced stress, and can be lifted and cleaned by hose without swinging to achieve mobile cleaning.

Usage Method

1 Drive mode:

The PSR nozzle uses the internal impeller of the fluid-driven nozzle as the power source. It does not need to be connected to the power supply and air source. It only needs to be connected to the pressurized cleaning pipeline to realize automatic cleaning.

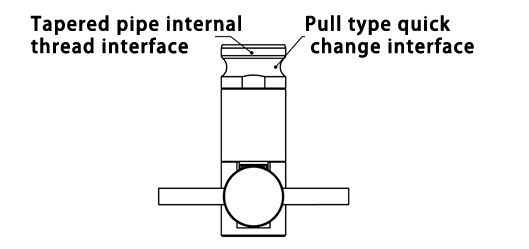

2 Installation method:

As shown in the figure, this product can be threaded or quick-change connected (sanitary fittings need to be customized).

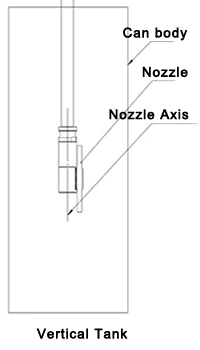

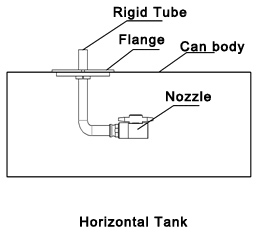

3. Method of placing the nozzle in the tank:

Because the nozzle uses the spherical cleaning technology of spherical space 360, the cleaning track is similar to the longitude and latitude of the earth, and the cleaning track at the two poles of the globe is denser than the track near the equator. Therefore, in order to make the nozzle work in the best condition, the nozzle axis should be overlapped or parallel to the axis of the tank body as much as possible. That is, let the two poles of the spherical network track, that is, let the area with dense track clean the position far away from the nozzle, and let the nozzle be placed in the center of the tank as much as possible. As shown in the figure, if it is an irregularly shaped can body, please place the axis of the nozzle along the direction of the far cleaning distance. Place position horizontal tank.

Matters Needing Attention:

1 It is forbidden to screw the nozzle base arbitrarily to avoid damaging the reducer.

2. Through low flash point fluid, such as gasoline, nitrogen replacement and nozzle grounding are required to prevent explosion or combustion due to fluid impact.

3 The nozzle shall not pass through high temperature and high pressure gas to prevent high-speed rotation from damaging the sealing ring.

4 When the working environment is flammable and explosive, air replacement shall be carried out before cleaning.

5 When the workplace is flammable and explosive, please connect the nozzle to the ground wire to prevent static sparks.

6 If the cleaning fluid is not clean, install a filter to prevent the nozzle from clogging.